R&D

State-of-Art R&D Facility

Asymmetric Hydrogenation Platform

·Asymmetric C-C bond formation and hydrofunctionalization

·Enantioselective catalysis

·Track record of improved chiral selectivity

Green Chemistry

·Use greener solvents

·Development of next-generation solid phase catalysts

·Average of 20-50% less waste generated

Cryogenic Chemistry

·Extensive knowledge in preparing aromatic boronic acid, aldehyde, acid and ester products

·Total 3 reactors with cryogenic capacities (down to -85 oC)

Hydrogenation

·Heterogeneous & homogeneous catalysis

·Replaced 20+ traditional reactions

·Hydrogenated 2,000+ different substrates

·Pressure: up to 100 bar

·Temperatures: up to 250°C

·Reaction volumes: up to 3,000 L

Other types of reactions

·Anhydrous anoxic reactions

·Cyanation (Manufacturing scale)

·Halogenation

·High pressure reactions

·Metal-catalyzed

·Enzymatic catalysis

·etc.

Kilo Lab & Pilot Plant

Kio Lab

- 10,000 SF facility

- Kilo-scale non-cGMP custom synthesis

- 5L to 100L glass reactors in Howorth full containment fume booth

- Asymmetric hydrogenation platform

- Hastelloy C hydrogenation reactor (~10 MPa)

- METTLER TOLEDO RC1 Reaction Calorimeter

- Processing temperature range: -80ºC-200ºC

Pilot Plant

- 30,000 SF facility

- China FDA inspected GMP facilities

- 2 flexible GMP production lines

- 20+ reactor suites with glass lined reactor ranging from 50L to 5,000L

- 1,000L cryogenic reactor

- 500-2,000L hydrogenation reactor

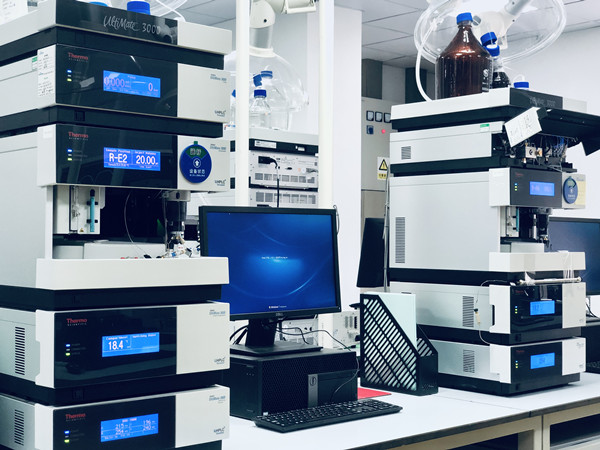

- QC lab with 3Q-qualified equipment

Manufacturing Site

cGMP Production

- Equipped with refining-drying-packing workshop (for API) and cleanliness level is D

- 89 reactors (1,000L-10,000L) in total

- 4 glass-lined crystallization kettle (2,000L-10,000L)

- 1 stainless steel distillation column (12,000L)

- 1 stainless steel distillation column (10,000L)

- 4 Glass-Lined Steel Column (1,500L, for high vacuum high temperature)

- Equipped with centrifuge, double-tapered Rotary Vacuum, pulverizer

- Equipped with 30T/H purified water unit, brine unit (salt temperature -35°C)

- Equipped with ethylene glycol cooling system (temperature 10-15°C), circulating water system

- Equipped with nitrogen generator, vacuum pumps and air compressors, etc.

Waste Treatment Capacity

- Invested more than US$20 million

- Has already built a set of modern environmental protection unit and sewage treatment implementation

- Waste gas treatment capacity: 40000Nm³/h

-

Total wastewater treatment capacity: 500m³/d

- Equipped with three effect evaporator, RTO incinerator, falling film absorption column

- Equipped with alkali washing tower, water washing tower, atomization tower

- Equipped with quench tower, high altitude chimney

- Equipped with automatic waste gas treatment control system and supporting sewage treatment tank etc.

Quality & Compliance

Compliance

Quality Assurance (QA)

·Leads company-wide cGMP compliance program

·Successful 10+ customer compliance and 3rd party GMP audits per year

·Maintain and invest heavily in compliance program and continuous improvement

Quality Control (QC)

·Fast turnaround and Best quality

·Dedicated by extensively trained QC group

·Assuring the integrity of raw materials, in-process control and final product testing

© Copyright 2023 Shandong Longzen Pharmaceutical Co., Ltd